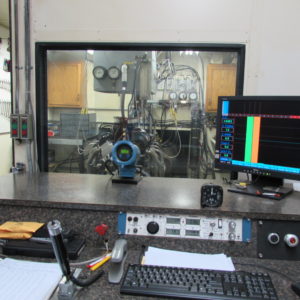

Engine Dyno

Are you looking to have your racing engine dyno tested? Look no further than the state of the art Froude Dyno system with D-Pac Acquisition at Kistler Engines to help you get the most out of your motor.

Engine Dyno Photos

Engine Rebuilding

With careful and thorough engine maintenance after each night of racing, dirt cars require engine rebuilding after an average of 10-20 shows. That process will include head reconditioning, block honing and replacing parts such as pistons, rings, gaskets, bearings, roller lifters and valve springs.

Oil pumps are disassembled, cleaned and inspected. Mag rebuilds may be necessary and flow testing may indicate the need for fuel pump rebuild. Cranks are magnafluxed and polished. Rods are magnafluxed and reconditioned and blocks are hot pressure tested to inspect for any cracks. Every engine undergoes “break-in” and is Dyno tested.

Rebuilding an engine requires personnel skilled in each specialty area and Kistler Engines provides that expertise with Paul’s 24 years in engine building and his employee’s combined 55+ years building dependable, highly competitive engines.

Fuel Pump Testing

Do you need fuel pump testing? In need of having your fuel pump flowed? Let us check your system on our Waterman Flow Bench.

Engine Boring & Honing

We precision bore on our CNC machine and hone on our Sunnen CK 21.

Engine Balancing

Balancing is performed using our Hines balancer.